Print an extra set of printed parts for your printer first just in case you break something! None of that is a reason to discourage someone from experimenting with what they have first. Once you are ready to spend the money on a better routing tool it’s probably time to build a different cartesian bot, this one more optimized for quick Pen Up/Down moves instead of long linear Z-axis. A PCB mill on the other hand is a long series of Pen Up / Pen Down moves. It’s designed for moving precisely across a large range of heights but only has to move one layer at a time. Really though, a 3d printer is a compromise tool when used this way.

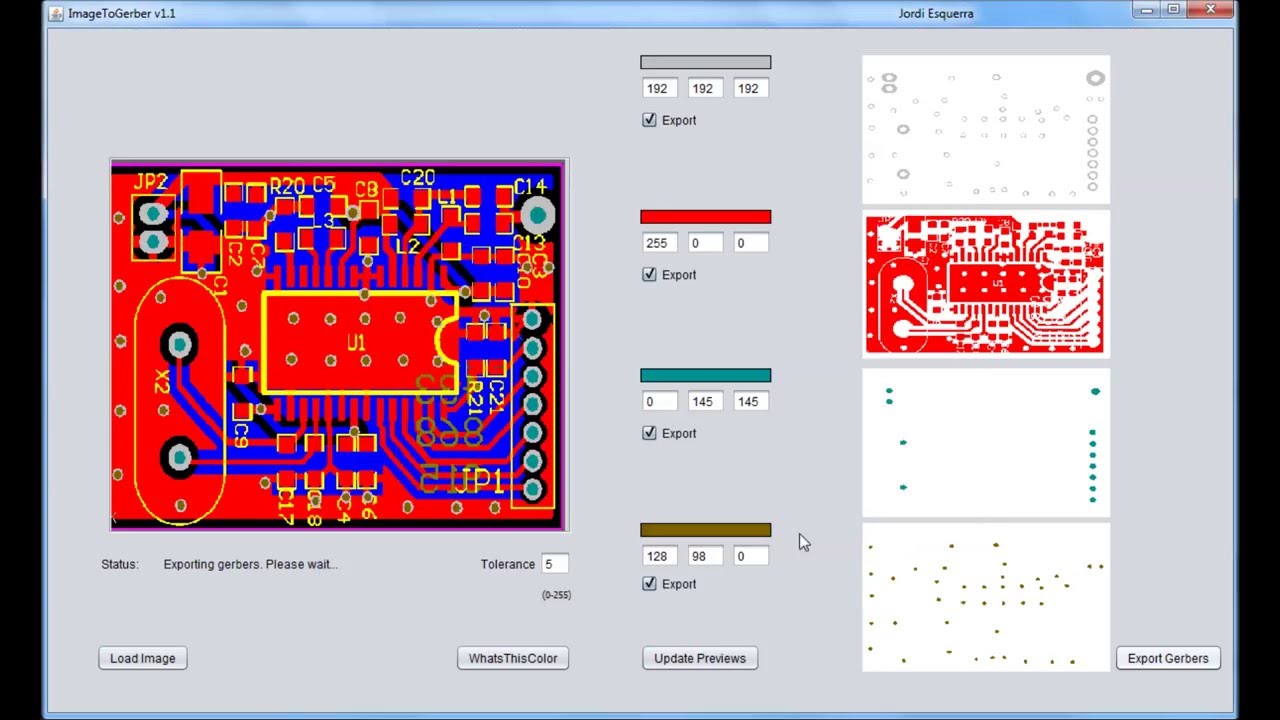

So, seeing that the process works with our printers, seeing that we have figured out the software path to go from our favorite PCB CAD packages to G-Code, when and if we start to long for greater capabilities THEN we can upgrade to something better. Those guys used their early 3d printers to etch the PCBs that run their later ones! Don’t try to tell me this cannot be practical when others have already succeeded! If that’s all one wants they can even use it this way for a while. It should be fine for through-hole projects. Who wants to spend the money for a good quality tool when it’s for a untested project? Instead we can perform this conversion with a Dremel first. Posted in 3d Printer hacks Tagged 3d printer, CNC mill, PCB milling Post navigation We’ve featured a few similar conversions before, such as this vintage conversion of a Makerbot and this cheap engraver conversion, but this one is much more detailed than those, covering the entire process from PCB design to final product. These are then fed to the 3D printer and cut in turn with an appropriate milling bit on the Dremel. That’s one for each side of the PCB, one for through holes and one for the final outline of the PCB. The excellent write-up that did on this hack describes how he converted the printer, and how he took an EagleCAD design and converted it into four GCode files. The result is an impressive PCB milling machine that can do double-sided PCBs and make through holes.

This approach means that the adaptations to the printer are minimal: the only hardware is a 3D-printed holder for the Dremel that replaces the print head. That’s the basis of this neat hack by, who converted an Anet A8 3D printer into a PCB miller by building a holder for a Dremel rotary tool and adapting the GCode. Got a 3D printer? With a bit of work, you may also have a PCB miller.

0 kommentar(er)

0 kommentar(er)